Palm oil extraction flow chart introduction

FAQ / Chat on line / Give me a price / Date:2022-06-16

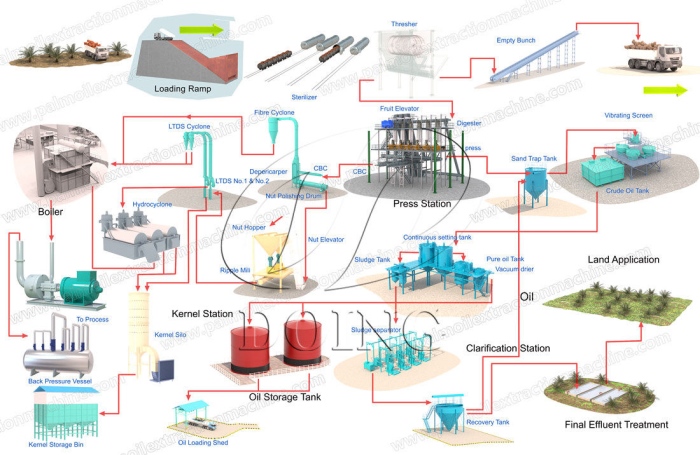

Palm oil extraction flow chart mainly uses the expression of graphical symbols, which can clearly express the structure of the whole palm oil plant and the operation process of the palm oil extraction. The entire palm oil extraction process involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil, purifying and drying the crude palm oil. At last, the filtered crude palm oil can be sold or be sent to refinery plant for the further process.

Palm oil extraction flow chart

Palm oil extraction flow chart

Palm oil extraction flow chart’s main stations:

| No | Main section | Main machine |

| 1 | Fresh palm fruit bunch reception section | Loading ramp |

| 2 | Sterilization section | Sterilization tank |

| 3 | Threshing section | Threshing Machine Platform |

| 4 | Digesting & Pressing section | Digester & Screw presser |

| 5 | Oil clarification section | (1) Oil clarifying tank (2) vibrating screen (3) plate filter |

| 6 | Oil drying section | Oil drier |

| 7 | Palm kernel recovery section | (1) Fiber and nuts separator (2) Palm kernel cracking and separating machine |

Palm oil extraction flow chart introduction:

1.Fresh Palm Fruit Bunch Reception Section:

FFB means fresh palm fruit bunch which can be harvested all the year round. After cutting from palm trees, fresh palm fruit bunch must be processed within 2days, or the acid value will be high and affect the final palm oil quality.

2.Sterilizing Station

The FFB are discharged into the loading ramp, then transported to sterilizer for sterilization. It uses high temperature to soften the fruit and kill the bacteria, and this will increase the moisture content of fruit and separate the fruits easily, so finally it will easy to get oil and separate palm kernel, also avoid the raising of free fatty acid. From picking to sterilization, the time shall not be over 48 hours.[ Relared reading: Why palm fruits need to be processed within 48 hours? ]

Vertical palm fruit sterilizer

Vertical palm fruit sterilizer

3.Threshing Station

Through the threshing, the palm fruits and empty fruit bunches(EFB) would be separated. Fruit Elevator will convey the threshed palm fruit to next step of palm fruit pressing station. [Related reading: Palm fruit thresher machine ]

*The EFB can be stored to be use as fuel or fertilizer.

Small scale palm fruit thresher machine

Small scale palm fruit thresher machine

4.Digesting & Pressing Station

The palm fruits would be transported to the digester and digesting is to crush palm flesh, which makes palm flesh to be puree. Then, double screw palm oil presser would process the puree to get crude palm oil.

Double screw palm oil press machine

Double screw palm oil press machine

5.Oil Clarification Station

Oil clarification requires three equipment, which are oil clarifying tank, vibrating screen and plate filter. The equipment can remove the fibers and impurities, making the crude palm oil cleaner. Besides, the station improve the quality of palm oil.

6.Oil Drying Station

Filtered crude palm oil would be dried by the oil drier, which evaporates the water in oil and is good for storage.

7.Kernel Recovery System

Kernel recovery system requires two machines. The fiber and nuts separator would separate the palm nuts from fiber. The clean nuts will be cracked and we get the kernel and shell mixture. Finally, the kernel and shell is separated to obtain the clean palm kernel. Cracking and separating would be operated in palm kernel cracking and separating machine. The palm kernel will be dried for storage or be sold to others or be processed into palm kernel oil by palm kernel processing plant.

Palm kernel cracking and separating machine

Palm kernel cracking and separating machine

The above is the mainly introduction of palm oil extraction ( suitable for capacity above 10tph ). Any question about palm oil mill process flow chart and any palm oil processing machine, please feel free to contact Henan Glory Company.

Call us

Call us Chat online

Chat online