HomeFAQWhat are the similarities and differences in the production process of palm oil and palm kernel oil?

HomeFAQWhat are the similarities and differences in the production process of palm oil and palm kernel oil?

What are the similarities and differences in the production process of palm oil and palm kernel oil?

FAQ / Chat on line / Give me a price / Date:2023-07-21

We can get two kinds of oils from palm fruit: palm fruit oil and palm kernel oil. Whether it is from the nature of raw materials or the production process, they are two different oils. Many clients will misunderstand the production process of palm oil and palm kernel oil. Next, I will introduce the production process of palm oil and palm kernel oil and production equipment respectively.

Palm oil production equipment

Palm oil production equipment

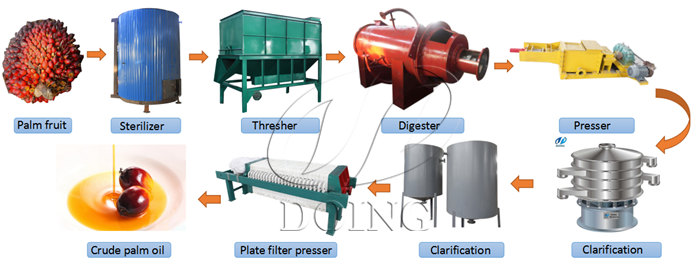

The production process of palm oil and palm oil production equipment

◆Step 1 Putting the palm fruit bunches into the sterilization tank for cooking. It has two purposes: on the one hand, it increases the humidity of the palm fruit, which is beneficial to the separation of the fruit from the fruit bunches; On the other hand, it destroys the activity of the fat-decomposing enzyme and prevents the content of free fatty acids (FFA) from increasing, so as to slow down rancidity.

◆Step 2 Conveyor scrapers will transport the palm fruit bunches in the fruit cages to the thresher.

The threshing station usually adopts a drum type threshing machine, which is generally 2.5 meters long, and the longer it is, the better the threshing effect can be guaranteed. Through palm oil production equipment, palm fruit will be separated from the palm fruit bunches.

Palm oil press equipment

Palm oil press equipment

◆Step 3 Conveying auger will transport these palm fruits to the palm fruit digester.

The pulp is stirred and broken in the digester tank and becomes finely divided, which can improve the oil yield. In addition, a portion of the oil produced during the digesting process can be collected in the lower oil collection tank. The oil presser is generally placed under the digester to facilitate timely pressing. Henan Glory Company can provide different types of palm oil production equipment which can be chosen according to processing capacity or your requirements.

◆Step 4 Filter impurities in the crude palm oil

At this stage, the palm oil production equipment we used usually is a vibrating screen, an crude oil clarification tank and a plate filter to get clean crude palm oil. Then use a vacuum drying system to evaporate excess water for easier storage. Finally, the clean crude oil is introduced into the crude oil tank for temporary storage. At this point, the production process of palm oil is completed.

Palm kernel oil production equipment

Palm kernel oil production equipment

The production process of palm kernel oil and palm kernel oil production equipment

◆Stage 1 Fiber separator to remove the fibers from the palm nuts

After the palm nut with fibers enters the separator, the built-in triangular axis rotates at high speed to break the palm nut and fibers apart. The processing capacity of the fiber separator is 2-4TPH, with a large processing capacity and high efficiency, which can achieve good separation effect.

◆Stage 2 Palm kernel cracking and separating

At this stage, the palm kernel oil production equipment we used is palm kernel cracking and separating equipment. Palm nuts enter the bucket elevator from the feeding port and are evenly fed into the magnetic separator. The shell and palm kernel are transported to the bucket elevator by the auger, and then transported to the air separation column. Under the action of cyclone and fan, the kernel and shell separation is realized by using the difference of specific gravity of kernel and shell. The separation rate can reach up to 95%-97%.

Palm kernel cracking and separating machine

Palm kernel cracking and separating machine

◆Stage 3 Palm kernel preteatment and pressing to get crude palm kernel oil

At this stage, the palm kernel oil production equipment we used is a double roller crusher, which with better crushing effect. The crushed palm kernels are then ground into a frying pan to adjust the temperature and moisture content. The moisture content before pressing needs to reach about 10% to achieve the best pressing effect. Palm kernels that have reached a certain moisture and temperature are fed into the oil press through a bucket elevator, and a small scraper is installed in the fan above the feeding port to ensure uniform feeding.

◆Stage 4 Filter crude palm kernel oil into clear palm kernel oil

The filtering process is relatively simple. A relatively clean crude palm kernel oil is available through the plate filter.

To sum up, the production process of palm oil and palm kernel oil are obviously different, but both have pretreatment, pressing and filtering stages, which are essentially the same. But due to the different properties of the materials, we need to use different equipment. Henan Glory company can provide palm oil production equipment and palm kernel oil production equipment. If you need. Please contact us freely.

Call us

Call us Chat online

Chat online