What is cooking oil filtration machine? How to choose it in palm oil production process?

FAQ / Chat on line / Give me a price / Date:2022-09-07

Cooking oil filtration machine is a equipment which can separate oil, solid impurities and moisture. There are different types of cooking oil filtration machine in market, and you can choose suitable one based on your requirement.

In the whole palm oil production process, it needs plate filtration machine, Leaf filtration machine, centrifugal filtration machine, security filtration machine, etc. As for how to choose, you need to know their use and the aim you want to get.

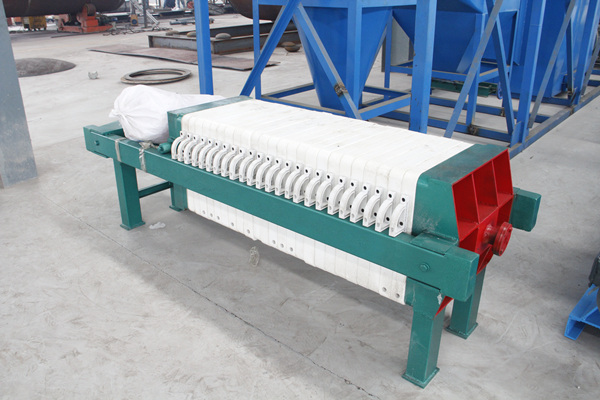

1. Plate filtration machine

Plate filtration machine

Plate filtration machine

Plate filtration machine is usually used to filter crude palm oil after pressing and clarification, to remove the fiber and some coarse particles. Plate filter adopts traditional oil filtering process, using the filter cloth to receive the impurities, so need to change the filter clothe manually.

Plate filtration machine is a little inconvenient when change filter clothe, but it is really suitable for small scale palm oil production factory, because it has low cost and high efficiency.

2. Membrane filtration machine

Membrane filtration machine

Membrane filtration machine

Membrane filtration machine is similar with plate filtration machine in working principle and structure, but is different in inner structure of filter plate.

The filter chamber of the plate filtration machine is formed by staggered splicing of two kinds of filter plates, one solid filter plate and one frame filter plate. Membrane filtration machine adopts two different filter plates, one is solid filter plate and the other is hollow filter plate. The frame filter plate is surrounded by four strips, and the hollow filter plate is cast together in two layers, forming a large gap in the middle of the filter plate, which is the hollow filter plate.

Because of different inner structure, the press effect of membrane filtration machine is better than that of plate filtration machine, and the price is also higher. Generally, in palm oil fractionation process, our engineer advises to use membrane filtration machine to separate palm olein and palm stearin.

3. Leaf filtration machine:

Leaf filtration machine

Leaf filtration machine

Leaf filtration machine is widely used in most of palm oil refinery plant and large scale palm oil production process. It is the best filtration method for solid-liquid separation.

Leaf filtration machine is mainly composed of oil tank, hoisting mechanism, stainless steel filtration meshes, vibration system, pressure display, slag discharging valve and other. It’s advantage is compact size takes up small plant space; reasonable design requires less labors but still ensure high efficiency, easy to operate and maintain for long-term performance, provide ideal solution for oil filtration blocking and stumble oil discharging. So usually if customers want complete palm oil production plant, leaf filtration machine is the most economical and suitable for them.

4. Centrifugal filtration machine:

Centrifugal filtration machine

Centrifugal filtration machine

Centrifugal filtration machine is the most automatic equipment, which is usually used in continuous type palm oil refinery plant. Crude palm oil is rotated at high speed, then oil, water and impurities can be separated rapidly by different centrifugal forces. The separated impurities are attached to the impurity collecting cover. You only need to clean the cover regularly. Although centrifugal filtration machine is the most expensive, its running cost is lower and has best filtration effect.

All in all, if you want to choose a proper oil filtration machine, you need to consider these three questions. 1)What processing capacity is the machine you have? 2)How much money you want to invest for the palm oil production plant? 3)Do you want higher automatic or lower automatic machine? Then tell us your requirement, and our sales and engineer will give you suggestion.

Call us

Call us Chat online

Chat online