How to choose palm oil processing machine?

FAQ / Chat on line / Give me a price / Date:2022-12-30

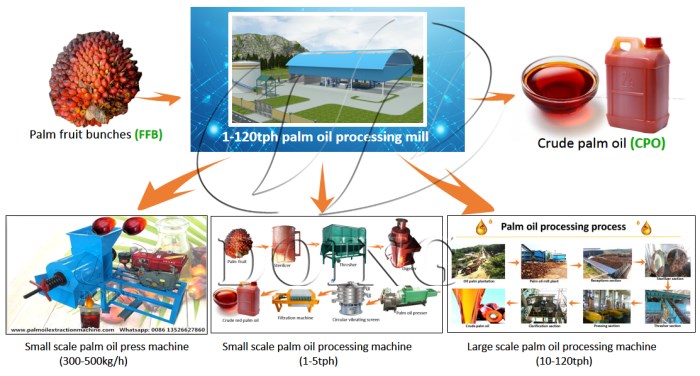

Henan Doing Glory Company is a professional palm oil production machine manufacturer. According to the different needs of customers, Henan Doing Company has the ability to design and provide kinds of palm oil processing single machine and palm production lines to choose. Here are some combined production line setup plans for customers to understand how to choose palm oil processing machine.

Display picture of combined production line setup plans

Display picture of combined production line setup plans

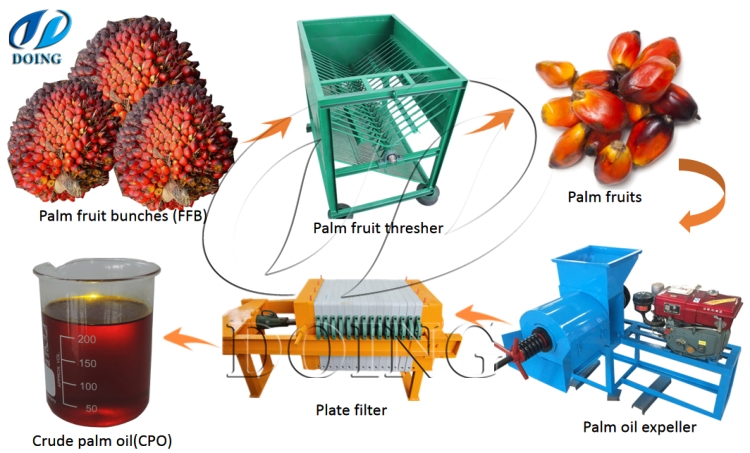

If your processing capacity is 500kg/h-2t/h, the simple palm oil processing machine would be a good choice for you. Simple palm oil processing machine is mainly composed of a simple palm fruit thresher, a screw palm oil press and a plate and frame filter.

500kg/h-2t/h simple palm oil processing machine are as follows:

Simple palm oil processing machine

Simple palm oil processing machine

1.Simple type palm fruit threshing machine:

Simple type palm fruit threshing machine is a kind of machine that is used for separating palm fruit from palm fruit bunches in palm oil production process. The common processing capacity of simple type palm fruit threshing machine 0.5-2 tons per hour.

2.Screw palm oil press machine:

The major function of screw palm oil press machine is to extract palm oil from palm fruit. As for 500kg/h-2t/h palm oil processing machine, there two kinds of screw palm oil press machine for people to choose. One is 500kg/h screw palm oil press machine, which has diesel and motor power system, the other is 1-2tph double screw palm oil press machine.

3.Plate and frame filter machine:

Plate and frame filter machine is an important filter device. The plate and frame filter uses filter cloth to filter various impurities in the grease layer by layer. Impurities form a filter cake, which can also take away part of the water and discharge it through the filter to ensure oil quality. What is more, There is another option, the automatic temperature-controlled vacuum filtration integrated oil press can be chosen which can realize one machine for two purposes, completing the pressing and filtering. In all, this line has advantages of lower cost and become a good choice for customers having limited budget on machines.

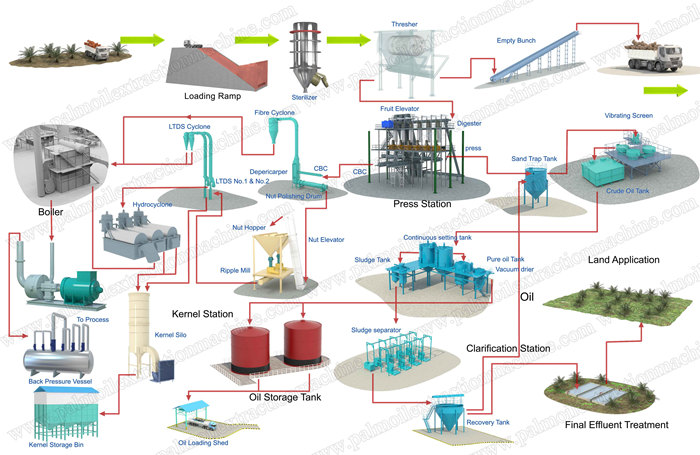

The main palm oil processing machines included in the automatic production line of small, medium and large are thresher, sterilizing tanks, digesting tanks, screw oil presses, vibrating screen, oil clarification tank and plate and frame filter. It is suitable for 1-5t/h small processing capacity and medium and large processing capacity from 10t/h to 120t/h. Therefore, you can choose suitable production line according to your actual processing capacity. Apart from these main machines, we can help customers design site planning and provide supporting facilities.

The main palm oil processing machines are as follows:

Automatic production line of small and medium

Automatic production line of small and medium

FFB(palm fruit bunches)--Sterilizer--Thresher--Digester--Screw press--vibrating screen/oil clarification tank/plate and frame filter--Crude palm oil.

1.Raw material:

FFB: It means fresh palm fruit bunches, you can get FFB from palm plantation.

2. Sterilizing section:

There are three types of sterilizers to choose in palm oil processing machines. All use high temperature of 145°C to soften and sterilize the fruit bunches. Boiled sterilization tank directly burns hot water to generate steam for heating and the sterilization time is 90-120 minutes. Cooking sterilizing tank is heated by steam, and the fermentation time is 60-90 minutes. Another is a vertical steam sterilization tank, which is heated by a peripheral heating coil and has a sterilization time of 60-90 minutes.

3.Threshing section:

Thresher in palm oil processing machines is mainly for separating palm fruit from palm fruit bunches. Henan Doing Glory can provide drum thresher machine, generally 2.5 meters long, which is beneficial to get better effect of threshing. After threshing, palm fruit and empty palm fruit bunches will be separated effectively and it is beneficial to the next digesting section.

4. Digesting section:

Digester in palm oil processing machines is crushing palm pulp and break the cell of pulp, and it is equipped with a steam coil on the outside, which is steamed again while steaming. There are horizontal and vertical digesting tanks, and currently the vertical type is used more because the digesting effect is better.

5. Screw palm oil press machine:

Presser in palm oil processing machines often use double-screw press machine. In terms of material, our screw press adopts 2Cr13, wear-resistant alloy steel, integrated casting process, and has a service life of 1000 hours. The pressure of the oil press comes from the simultaneous action of the front screw and the rear reducer, and is equipped with a hydraulic pump station (pressure is 100Mpa) and a hydraulic cylinder. The spring pressure can be adjusted, and the pressure in the cavity can be detected in real time and adjusted in time, so as to achieve optimum pressing effect.

6.Clarifying and filtering section:

Clarifying and filtering machines are mainly for removing some impurities. The crude palm oil can be gotten by sedimentation, filteration and separation, using vibrating screen, oil clarification tank and plate and frame filter. They can be configured based on customer needs.

If the processing capacity is large enough or needed, the following palm oil processing machine can be added to the production line.

Large palm oil processing machine

Large palm oil processing machine

7.Palm oil production fiber separation section:

After pressing, the filter cake is crushed by the crushing screw conveyor and then sent to the fiber separation air net and fiber polishing roller for fiber separation.

8.Kernel recovery section of palm oil production:

the separated husks are sent to the warehouse for temporary storage, and used as fuel for the boiler room when necessary; the dried kernels are sent to the kernel storage for storage, and a palm kernel pressing production line can also be configured if necessary.

9.Palm oil production sewage treatment section:

The pool sewage treatment system is the most common and effective treatment method. None of these are necessary, and it is mainly based on your needs to decide whether to configure or not.

Henan Glory Company has been committed to the research and development and design of palm oil processing machines for 11 years. Among them, single machines such as threshing machines and pressers can be used alone or selectively purchased according to your requirement or can be used in conjunction with the production line. The equipment has been sold to many countries and we have helped to build local factories successfully in many regions. In addition, we can also provide palm kernel oil processing machines or refining machines for people to choose. Moreover, our engineers can help customers design production lines, provide installation services and guide the use of machines, and meet customers' customized requirements for palm oil production. If you need any palm oil related machines, please feel free to contact us.

Call us

Call us Chat online

Chat online