Effective palm oil mill effluent treatment solutions

FAQ / Chat on line / Give me a price / Date:2025-01-17

Palm oil mill effluent usually comes from palm oil production process such as oil pressing and refining. It has the characteristics of high organic matter content, suspended matter and solid content, large acid-base fluctuations, and difficult-to-degrade pollutants. If these characteristics are not properly handled, the effluent will cause serious pollution to the surrounding environment. Therefore, it is particularly important to adopt a scientific and effective wastewater treatment solution. So, how to deal with palm oil mill effluent ?

As a producer of palm oil processing equipment, Henan Glory has always paid attention to environmental protection and sustainable development, and is committed to providing customers with environmental protection equipment and efficient and environmentally friendly palm oil mill effluent treatment solutions to help companies achieve green production, energy conservation and emission reduction, and improve resource utilization. The following are effective palm oil mill effluent treatment solutions for you.

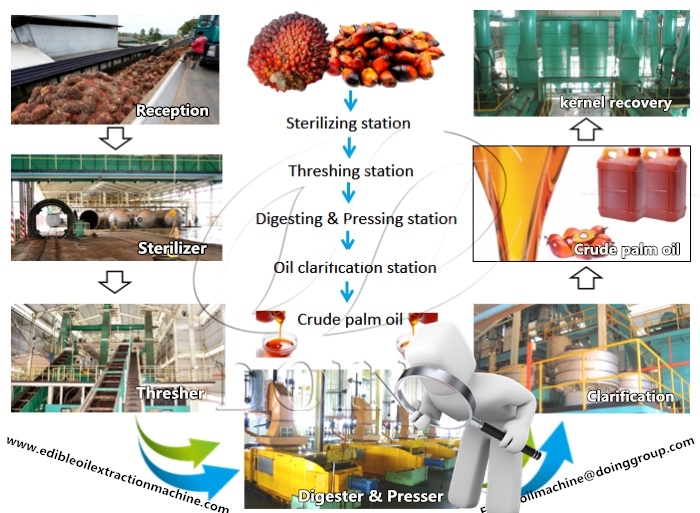

Palm oil processing line

Palm oil processing line

To solve the problem of palm oil mill effluent treatment, the specific plan is as follows:

Primary pretreatment

The primary pretreatment stage is mainly to remove large suspended solids and oil components in wastewater. Commonly used technologies include:

Mechanical filtration: Use filters or vibrating screens to remove larger solid particles.

Oil-water separation: Use an oil-water separator to separate the grease in the wastewater, reducing the burden of grease on subsequent treatment links.

This stage can effectively reduce the suspended matter and grease content in the wastewater, providing a cleaner water source for subsequent treatment.

Biological treatment

Biological treatment is the most common palm oil mill effluent treatment solution. By utilizing the metabolism of microorganisms, organic matter in palm oil mill effluent is degraded into harmless substances. Common biological treatment methods include:

·Activated sludge method: The microbial community in the aeration tank decomposes the organic matter in the wastewater and converts it into carbon dioxide and water.

·Biological filter: The biofilm is attached to the surface of the filter material to degrade the organic pollutants in the wastewater.

·Anaerobic biological treatment: It is suitable for high-concentration organic matter in the wastewater. The use of anaerobic microorganisms for treatment helps to reduce COD (chemical oxygen demand) and BOD (biological oxygen demand).

The biological treatment method has the advantages of stable treatment effect, low cost and simple operation. It is the core link in treating palm oil mill wastewater.

Advanced Oxidation Processes (AOPs)

For difficult-to-degrade organic matter, such as phenolic compounds, conventional biological treatment methods may not be effective. At this time, advanced oxidation technology (AOPs) becomes an effective supplement. AOPs use oxidants such as ozone, hydrogen peroxide, and ultraviolet light to oxidize organic pollutants into low-toxic and harmless substances. Common advanced oxidation technologies include:

Ozone oxidation method: using the strong oxidizing property of ozone to degrade organic pollutants into water and carbon dioxide.

Fenton reagent method: using the reaction of iron salt and hydrogen peroxide to generate free radicals, destroying the molecular structure of organic matter and achieving degradation effect.

Advanced oxidation technology can not only improve the efficiency of wastewater treatment, but also reduce the concentration of pollutants in the water in a short period of time, ensuring that the discharged water quality meets national environmental protection standards.

Palm oil mill plant

Palm oil mill plant

Membrane technology

As a highly efficient water treatment technology, membrane technology can remove dissolved organic and inorganic substances in water through the selective permeability of the membrane. Commonly used membrane technologies include:

Reverse Osmosis (RO): It can effectively remove dissolved salts, heavy metals and other trace harmful substances in water, and provide high-quality recycled water.

Nanofiltration membrane (NF): It can filter out large molecular organic matter while retaining minerals in water, and is suitable for palm oil mill effluent treatment that does not require excessive desalination.

Membrane technology can achieve deep treatment of wastewater, which can not only significantly reduce the concentration of pollutants, but also realize the reuse of wastewater, which is in line with the company's sinable development goals of saving water and reducing emissions.

Sludge treatment and resource utilization

In the process of palm oil mill effluent treatment, sludge treatment is also an important link. Through dehydration, drying, composting and other treatment methods, we can make the sludge harmless and convert it into organic fertilizer for agricultural production to achieve resource recycling.

Environmental protection has become a responsibility that cannot be ignored in the modern oil and fat industry, especially for highly polluting enterprises such as palm oil mills. Our company also provides customized palm oil mill effluent treatment solutions for palm oil mills of different sizes and needs. Through preliminary water quality analysis, process evaluation and on-site investigation, we can tailor the most suitable palm oil mill effluent treatment system for customers to ensure the optimal treatment effect.

In addition, we also provide professional equipment and technical support, including: palm equipment supply and installation, regular technical training and operation guidance, long-term after-sales service and maintenance guarantee.If you have related palm oil mill effluent needs or technical consultations, please feel free to contact Henan Glory Company, and we will wholeheartedly provide you with a full range of services and support!

Call us

Call us Chat online

Chat online